Not even worth the time to argue, your so far from understanding what is going on inside a 2 stroke. You can't even see what is happening on the graph

Well that's your opinion backed by....................old wives tales? Even Bells book talks about this.

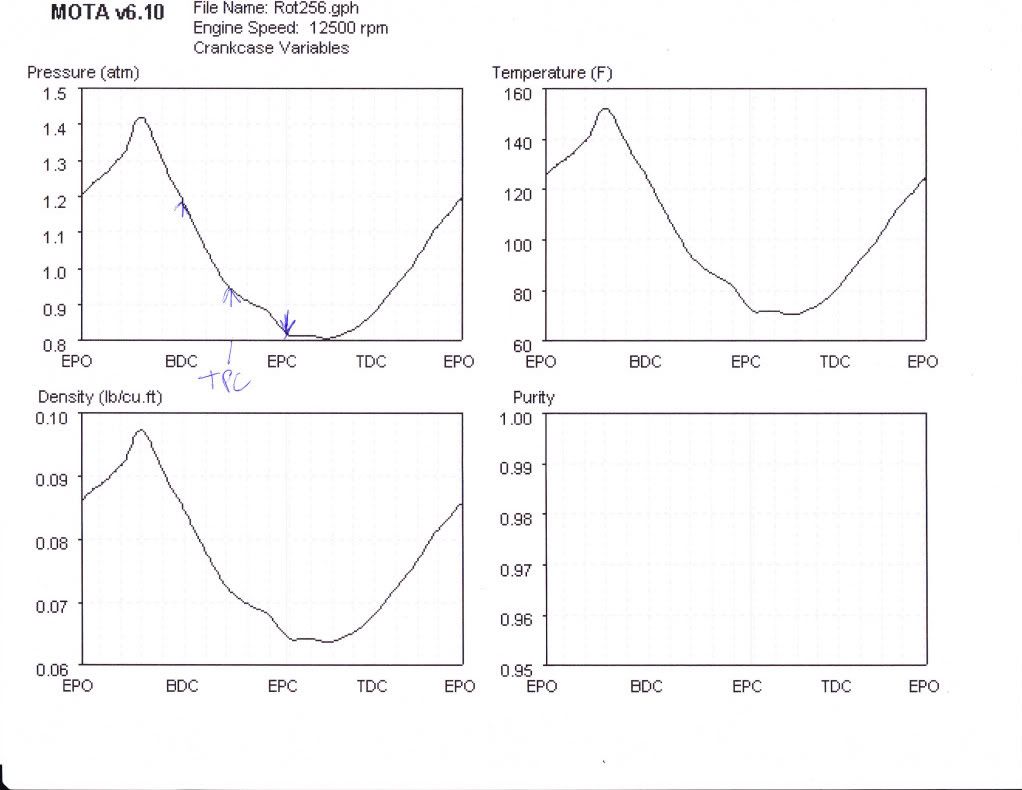

As explained before the highest pressure in the crankcase is lower than residual cylinder pressure.

Stated repeatedly, but neither 'explained' or 'proven'.

Please explain how the pressure in the cylinder (after blow-down) is higher than the pressure at the exhaust port.

Cheers, Daryl.

They are the same never said that port pressure was higher. I said higher than crankcase pressure

A trip down to Spec Savers must be on the cards  The blue trace clearly shows a spike after transfer port open,

The blue trace clearly shows a spike after transfer port open,

Let's try to keep our discussions to Real Facts,

Colour Blindness cannot be corrected with glasses from Spec Savers.

As we have been given no details on whether these are Real measurements, what the sample rate is, or if this is just a simulation, a small bump at this point is hardly proof of the proposition that: "Residual cylinder pressure ALWAYS exceeds crankcase pressure".

l

The graph suggests that the 'effective' TPO point is actually several degrees after the point indicated on the X axis.

Cheers, Daryl.

The blue and green overlay each other just shows the green

. The traces come from EngMod2T, that is taken from Blairs calculations validated by a South African Professor (who worked in Yamaha's GP program from the mid 80's to mid 90's) at the uni with about 30 Kistler pressure transducers connected to the YZ250 engine. Same 4T software is used by EVERY V8 Supercar team. The results are very much validated by simulated outputs perfectly matching "at the wheel" figures. Feel free to contact

http://www.vannik.co.za/index.htmI see so trying to convince me that with the transfers OPEN no matter how small that opening the decending piston will cause case pressure rise and "force" charge through the transfers?

Fuel is roughly 80deg C in the cases,

measured pressure has never increased by 5 times regardless of expansion and evaporation.

Look at the black trace just as the transfer opens the resonance in the inlet tract moves into the crankcase and again just as the case pressure drops from the ascending piston. red trace shows a corresponding rise in pressure.

I see pressure in the inlet tract rising as soon as IPC . (Piston ported engine, port closed)

Pressure rise from stopping the flow.

Pressure wave bouncing back and forward along the inlet.

No effect on case pressure at second pressure peak. (Piston ported engine, port closed)

Pressure rise in crank-case at 3rd peak corresponding to IPO. (Piston ported engine, port open)

Perhaps some-one can explain what is driving the intake pressure so Negative from 60degrees ATDC.??

The gradual pressure rise to TDC and beyond doesn't look like it's got the energy to do it.

Cheers, Daryl

Assumptions are mistakes awaiting discovery

Would be the first piston port engine ever with asymetric inlet timing

The black trace is the pressure trace at the end of the inlet tract. The inlet resonance peaks and troughs shift with rpm that's is just 1 rpm point 12,000 in a Rotax 128 engine. The resonance is not as important on the disc valve as on a reed valve, which (with a reed engine)you can with varying degrees of success shift the peaks to where you want them.

Yes effective opening of the transfers is a tiny bit later than when the window opens, as the port that opens first flows last.

Lozza, you wrote the "transfers are purple, green & blue", would the green & blue be each side transfer and the purple a rear boost/C port?

Excellent question, John.

The purple (pink) one is responding directly to the pressure drop at the exhaust port.

The green & blue appear to be responding to the pressure in the crank-case.

Cheers, Daryl.

Rotax 128 John @12,000 rpm.

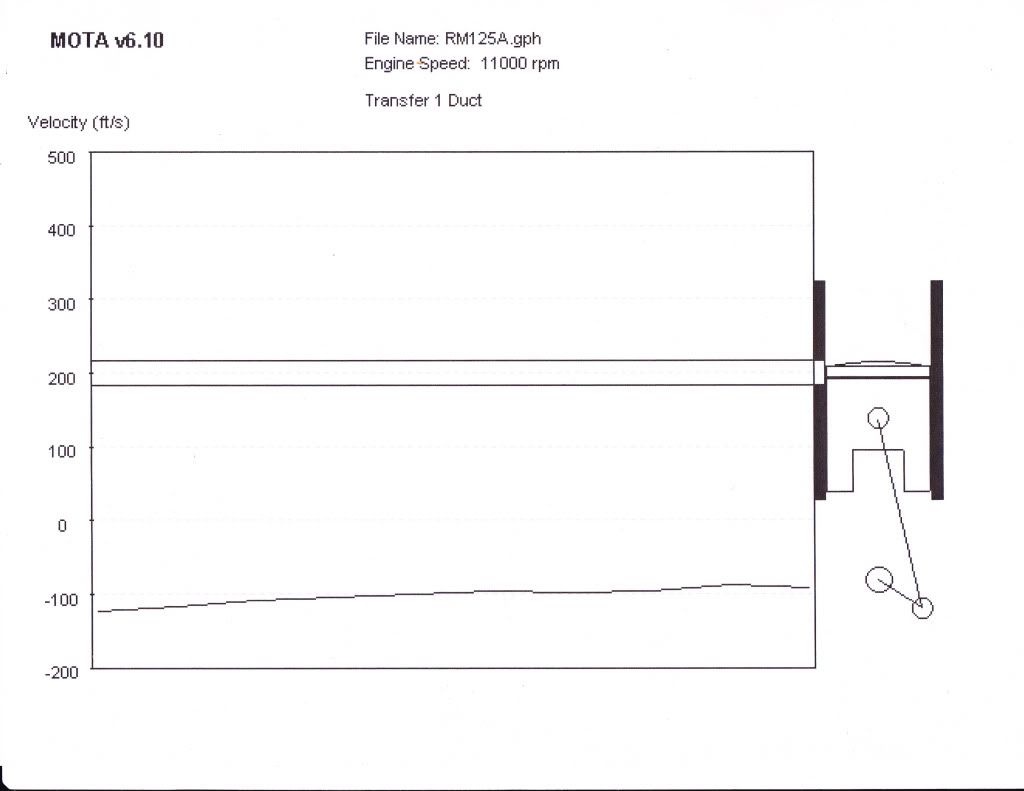

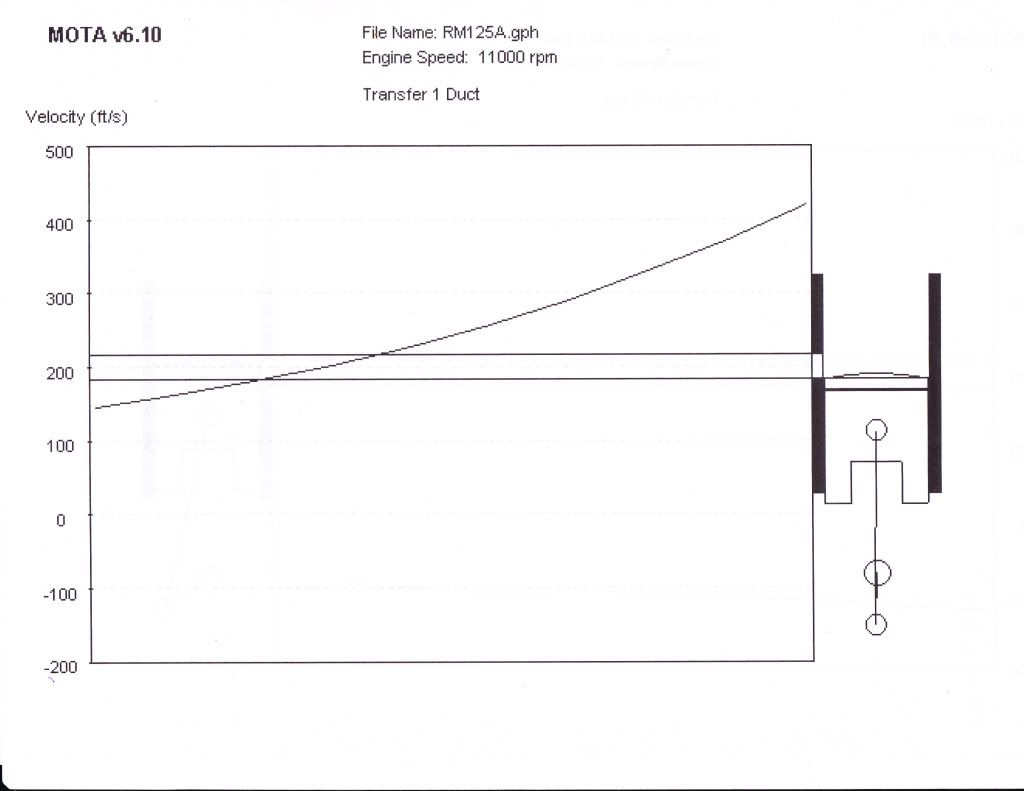

.........and that pressure comes from the cylinder not the decending piston. Here's an old MOTA shot showing velocity in a transfer port just after the transfer is open. Yes getting that mass in the transfers moving is the secret to a twostroke........... well one of them anyway.