Can’t say I have come across 3003 or 1100 while working in the trade.

5005 & 5356 are the common grades here in Aust.

Looking through the matweb site (it does seem a good site for info) 5005 & 3003 look to be almost identical in physical properties.

5005 is used for a lot of fabrication work where bending is required and strength isn’t overly important.

5356 has more strength than 5005 and will be a bit harder to work into shape although normal bending should be fine.

I have some plans to build some tanks in the future and I would just be using the 5005 in 2mm (0.80”)

As mentioned you can polish the bejeezus out of it but it is also more forgiving when welding and be more resistant to dents from knees.

The 2mm will fold fine but just be harder to form any dome type shapes.

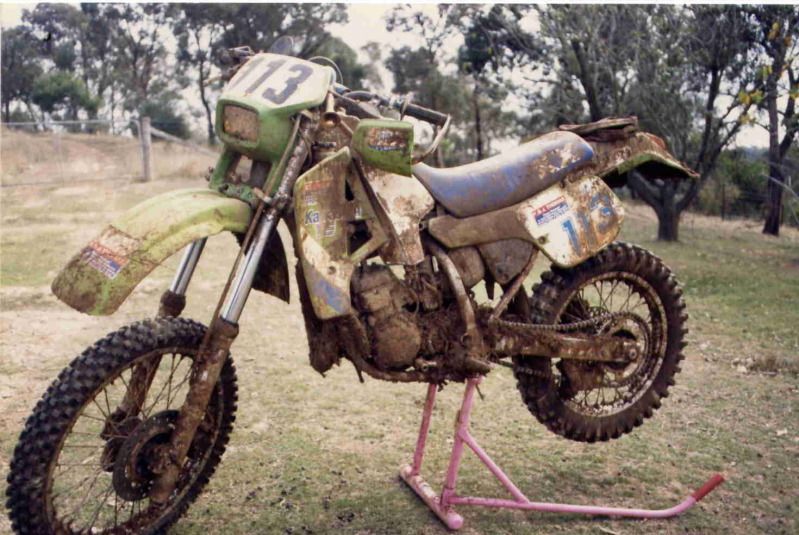

I slapped this one together in a hurry back in 87

It’s a bit crude actually but it did the job at the time.

I think I used 1.5mm 5005 at the time.

It ended up lighter than the plastic tank by a couple of ounces despite it holding nearly 3 litres more than stock.

I wasn’t chasing lightness at the time and it actually cracked a couple of times on me. Once at the Pyrenees Enduro after a big get off that also cracked the radiator. I managed to nurse it home for a finish by convincing myself that the leaking radiator would put out any fires from the leaking tank.

One thing a hated on that tank was the left side lower forward seam, it was too sharp and would rub on my leg, if I was to make another I would try to roll the bottom edge and have the seam under the tank instead of on the corner.