Have done the modification, fit a late model 6 speed shift detent system into an early 5 speed gearbox

Bike is 72 CR450 husky

Was hard to find neutral and kept finding false neutrals, was a pain on the track

Pictures tell the story

Trial run, neutral on the old detent in the hole on the bottom of the shifter drum and neutral on the new detent plate and roller arm on the top of the shift drum

Trial run to see if second lines up, yep -- "proves" that the degree rotation of a five speed shift drum is the same as the degree rotation of the 6 speed drum

Machining the boss on the top of the shift drum so that the late detent plate goes on, note - do not take any material of the drum itself - it is already the correct height, just make sure the surface is flat, mine had a small turn up near the edge so I got that flat.

The drum was case hardened, once you get through that it is nice steel to cut

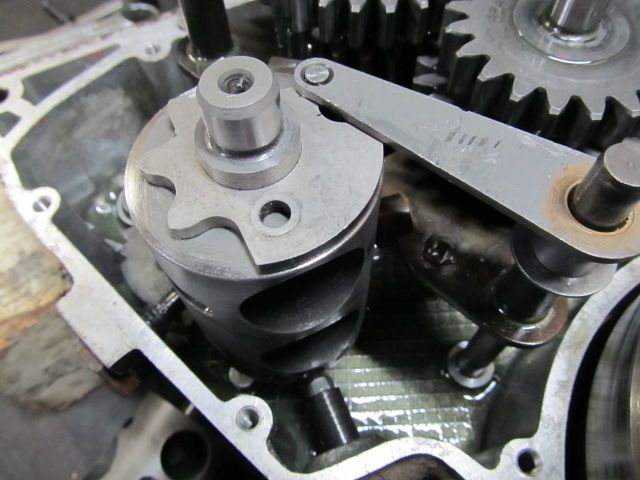

Test fit of the detent plate, neat fit - no play

Lock pliers to hold the plate in the correct position so it will be timed correct when taking it out to weld.

And be careful to have the shift pin standing up straight because it can lean over a little and you may not notice it and you will have incorrect shift detents for the gear engagement

Used an Arc welder, was not a neat weld, am usually ok but was crappy -- may be the case hardening?

The shift fork guide tube needs to be shortened to allow for the roller arm and spring assembly

cut off 6.63 mm

The new assembly has a height of 53.5 mm

The available space in the cases is not quite 53.5 mm so plus a bit for the gasket and then some allowance for working clearance all "adds" up to needing to remove .3 mm from the cases

Econo mill :-) my drill press with an end mill, take .3 mm of the boss for the shift pin to give the working clearance and also remove the crosshatch on the case so there is no catch point for the detent spring

Ready to assemble