G'day all

Im a first year sheet metal fabricator/apprentice i've been tig welding now for close to 10 months.I weld alot of 2-6 mm alluminum boat petrol tanks and actual boats on the odd occassion, i weld alot of 0.9-4mm brushed stainless for boat railings and such things and alot of them have to be polished to mirror finish aswell if any 1 needs any help wif that i can help to

haha . i've found alluminum welding to be the best by far it looks a treat when you can pull of a nice fillet and alluminum being the lightest of metals/alloys besides titanium its one of the best for building stuff for bikes with also

. when welding alluminum one of these badboys will be your best friend.>>

using one of these inox stainless steel on ur usual 5-7 inch grinder u can rip into the alloy surface ur about to weld to open the pores of it and remove any contamination giving you a easy and nice looking weld

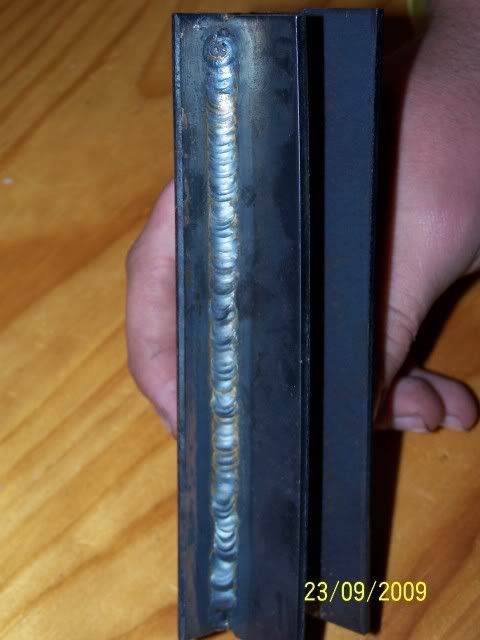

heres a 3mm mild steel fillet i performed to pass one of my tafe course sections>>

and heres a alluminum fillet i performed at work just having a bit of a muck round>>

having a clean surface area to weld is one of the best things you can do to make your welding life easier hope anything i said helped and good luck mate.

Cheers Tom