1

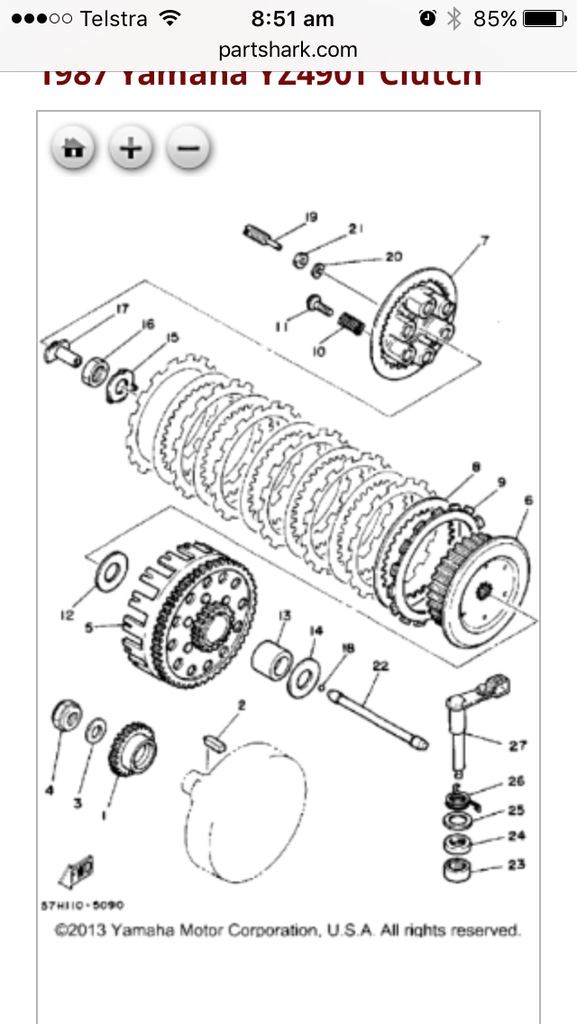

Yamaha / Re: Desperatly need clutch parts!!

« on: May 17, 2017, 10:01:09 am »give pennas mcycles in Bendigo a call as they used to be Yamaha and have a bit of old stock laying about

Thanks Mate. Tried them but no luck.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

give pennas mcycles in Bendigo a call as they used to be Yamaha and have a bit of old stock laying about

It's too late to try and get parts from the USA now as I leave in less than two weeks, so I'm really up shit creek.

It's too late to try and get parts from the USA now as I leave in less than two weeks, so I'm really up shit creek.

You can't just chuck in some rubber washer and leave the rear loose as it will tear the mounts to pieces in a very short time. If you where to rubber mount the motor you would need to bore out all the mounting holes in the cases and fit proper rubber mounts with inner and outer steel sleeves, especially needed would be an inner sleeve so the bolt can be done up tight. Even if the rear mount is left tight it wouldn't take long before it worked loose and the swingarm would be loose as it is the rear mount.

Your only practical quick fix would be some sort of rubber mounts for the bars. Other thing to think of would be a radical gearing change to get the motor RPM below the vibration at the speed you want to go at.

The vertical component of the engine vibration is the one causing the problem allowing the engine to pivot around the rear engine mount is how I have done it in the past. Harley handle bar mounts are a good source of isolation mounts (but for the imperial sizing)

Have you had the balance factor of the crank checked? It is quite possible to change the factor to a higher value which will move the vibration away from the RPM that is causing the problem.

Hey Gibbit

A few of the big bore two strokes that I have brought from the states have had lead shot in the bars

I guess they used shot gun balls to fill the bars.

Thought it might be worth a test and cheap.

Rubber mount the engine at the front and the head stay

are you still planning to run this at Finke ?

that is awesome.

johnny orchard started the thread i believe

there is a trick to extend the pilot jet deeper into the bowl with some hose to prevent the vibrations allowing air into the pilot circuit. this stops the pinging apparently